| |

| |

|

RAM Imaging carries HP Large and Small

Format Printers, KIP Analog and Digital Systems, Scanners,

Laminators, Cutters, Trimmers and Shredders.

As an Elite HP and KIP Partner, our

sales and service staff are manufacturer trained to

offer our clients a complete solution to best fit

their needs. We can provide you with finest equipment

and also back it up with skills and knowledge to ensure

that you're in business worry free.

RAM Imaging is your one stop equipment

and supplies provider. From printers to peripheral

items such as laminators, scanners, stackers, cutters

and trimmers - we cover it all and with our know how

will ensure you don't skip a beat. We also carry all

supplies such as inks, toners and media for all equipment

we sell.

|

|

|

|

|

|

|

|

|

| |

Vinyl cutters that set the industry standards for performance and value.

|

|

|

Refined in 2008, the new SummaCut Series is the product from decades of Summa’s brilliant European engineering. Numerous refinements have been made in the new Series, such as the OPOS X technology, known from our most advanced S Class cutting plotters, is now integrated into a newly designed drag-knife cutting head. SummaCut is capable of reading registration marks for contour cutting; not only on standard materials but also on reflective, holographic or mirrored materials, as well as through the many different types of laminates being used today. The SummaCut features highly complex algorithms to compensate for any deformation of the print, using the world’s most reliable sensor technology; this makes SummaCut a winning contour cutter for any sign or print shop.

Summa engineers also know the most important vinyl cutter feature is tracking. Every cutter we build starts with our exclusive and patented MicroSprocket™ media transport rollers. Milled from the finest materials, in a unique process that assures each roller has an exacting diameter, we then specially coat each roller to eliminate the risk of wear and oxidation that can degrade tracking over time. Summa’s world renowned quality craftsmanship delivers cutting performance and reliability that outclasses others’ top-of-the-line cutters. It’s no wonder the affordably priced SummaCut Series is one of the most popular vinyl cutters ever built. |

|

|

D75

– 30” (76cm)

vinyl and contour cutter

D120 – 48” (122cm)

vinyl and contour cutter

D140 – 54” (137cm)

vinyl and contour cutter

D160 – 64” (163cm)

vinyl and contour cutter |

|

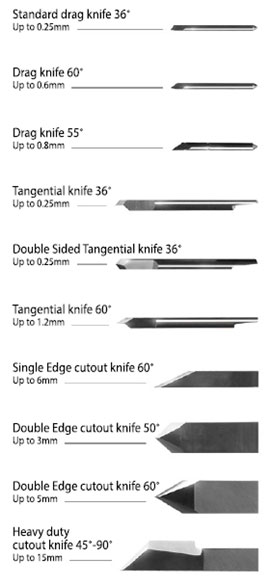

Drag

Knife with turbocut and tangential emulation modes |

|

|

D75=29.2”,

D120=47.2”, D140=53.1”, D160=62.2”

In Extended Mode you can achieve width of material |

|

|

0-400

grams in 5 gram increments |

|

WINPlot Cut software, Cutter control software,

2 standard 36° drag knife blades with holder, 1 fiber-tip

pen and pounce tool with holder and USB cable. |

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

NEW S2 Advanced vinyl and contour cutters for high-volume digital print and sign shop.

|

Contour cutting printed graphics has become the most important feature in vinyl cutting. Summa invented contour cutting in 1993 with the pioneering Optical Positioning Sensor (OPOS), the world's first marker recognition system for vinyl plotters. Since that time, Summa has continually refined OPOS technology while innovating many new advancements and enhancements that have redefined contour cutting.

Summa's next generation contour cutting machine will greatly enhance workflow productivity when cutting printed graphics, sign, labels, vehicle wraps and more. The S2 is available as a high-speed Drag Knife model (D Series) or as a true Tangential blade model (T Series), each standard equipment with OPOS-X. OPOS-CAM is available as a factory upgrade option on new machine purchases.

The most stable and reliable optical registration system available

- Uncompromising tracking capabilities

- Unrivaled repeatability

- Faster OPOS sensor for unparalleled accuracy and automation

|

|

|

An entirely new main processor that is 7 times faster than before!

The new processor shortens the amount of time needed for processing which means you have more opportunity to output more jobs throughout the day. This has also increased the speed of the USB communications, making it faster than ever before with the jobs you can process. |

|

| |

|

|

30-INCH (76 CM), 48-INCH (122 CM), 54-INCH (137 CM), 64-INCH (163 CM) |

|

High-Speed Drag-Knife (D Series); True Tangential (T Series) |

|

|

D75, T75 - 29.2 IN. (74.2 CM). D120 - 47.2 IN. (120 CM). D140 - 53.1 IN. (135 CM). D160, T160 - 62.2 IN. (158 CM), Extended Mode: Width of the Material |

|

Up TO 56 in./sec.

(1414 MM/SEC.) MAX |

|

Drag: 0-400 grams (14.11 OZ), , in 5 gram steps; Tangential: 0-600 Grams (21.164 OZ) |

|

|

WINPlot or MACSign cut software, cutter control parameter software, standard 36° blade holder, 2 standard 36° blades, 1 fiber-tip pen, pounce tool and holders

- Optional Motorized Take-Up Roller Available for S2 140 & S160

- Optional Media Rack Available for S2 140 & S2160

|

|

|

|

| |

|

|

|

| |

|

|

|

|

Introducing the most versatile and affordableflatbed cutting system available.

|

With the F Series, Summa launches a completely new cutting product line based on expertise gained from over a quarter century building the world’s finest cutting plotters. These advanced engineered flatbed cutting tables are designed for cutting sheet and rigid materials, as well as roll stock. Up to three tools can be inserted at one time into the multi-module tool holder. Changing tools is quick and easy thanks to an innovative single-screw fastening system. Automatic tool recognition, combined with digital and mechanical depth and pressure control, ensures precision cutting on a vast array of materials. The F Series base unit comes standard-equipped with a drag knife module and Summa’s revolutionary optical camera marker recognition system for unbeatable contour cutting accuracy. Multiple material-handling options assure optimal efficiency whether cutting printed flexible or rigid substrates. An ever-increasing arsenal of optional add-ons further expand the capabilities of the F Series, allowing for a custom-tailored machine perfectly matched to fit your specific workflow. |

|

|

|

|

92.5 x 76.3 x 43.3 IN. (285 x 194 x 110 CM) without roll support |

|

|

63 IN. (160 CM) Wide x 47.2 IN. (120 CM) Long up to 164 FT. (50 M) Long in Multi Panel |

|

Within +/- 0.05 MM on Plots |

|

0.05% of Move or 0.05 MM, whichever is greater |

|

Up to 39.4 IN./Sec (1000 MM/Sec) |

|

|

Vertical: 200 Newton

Horizontal: 200 Newton

|

|

|

3 Phase 208V+N or 3 Phase 230V or 3 Phase 400V+N |

|

|

|

|

|

|

|

|

|